Diesel Stove

Basic Operation

As soon as the stove is switched on the combustion blower that ensures sufficient oxygen supply to the combustion chamber starts running and fuel is pumped into the combustion chamber. The amount of fuel is not measured. Also the flow plug that is needed for pre-heating to ignite the fuel starts. The temperature in the ignition chamber is measured continuously. After the temperature is high enough the glow plug will continue to glow for a few minutes to ensure that the stove is properly burning, after that it will be switched off. If the required temperature is not reached within about 5 minutes the stove starts its shutdown cycle. No more than two startup attempts should be made to start the stove, otherwise too much fuel may be pumped into the combustion chamber, which can be dangerous.

When the stove is switched off the fuel pump is switched off immediately. The combustion blower continues to run in order to cool the stove down and to clean it. After the temperature has decreased below a threshold level the blower will continue to run at a lower speed for about 10 minutes for further cleaning.

As soon as the stove is switched on the combustion blower that ensures sufficient oxygen supply to the combustion chamber starts running and fuel is pumped into the combustion chamber. The amount of fuel is not measured. Also the flow plug that is needed for pre-heating to ignite the fuel starts. The temperature in the ignition chamber is measured continuously. After the temperature is high enough the glow plug will continue to glow for a few minutes to ensure that the stove is properly burning, after that it will be switched off. If the required temperature is not reached within about 5 minutes the stove starts its shutdown cycle. No more than two startup attempts should be made to start the stove, otherwise too much fuel may be pumped into the combustion chamber, which can be dangerous.

When the stove is switched off the fuel pump is switched off immediately. The combustion blower continues to run in order to cool the stove down and to clean it. After the temperature has decreased below a threshold level the blower will continue to run at a lower speed for about 10 minutes for further cleaning.

Issues and Remedies

After almost two years of struggling we are now more or less on terms with the stove. Diesel stoves are mainly used in (and probably designed for) use in boats in western countries. Main differences with use in an overland vehicle are:

As a consequence we ran into a number of issues.

Stove produces much smoke and flames can be seen through the ceramic plate

Stove does not start

After almost two years of struggling we are now more or less on terms with the stove. Diesel stoves are mainly used in (and probably designed for) use in boats in western countries. Main differences with use in an overland vehicle are:

- Stove is subject to shocks and vibration during driving

- Larger variations in operating altitude

- More variation in the fuel quality

As a consequence we ran into a number of issues.

Stove produces much smoke and flames can be seen through the ceramic plate

- Cause/remedy: we had this issue at 2000 m altitude, probably because the oxygen supply is too low. We solved it by turning the trimmer for the pump rate (R13) as low as possible (counterclockwise), lower than specified in the service manual.

- Cause/remedy: the aluminum burner heat shield below the combustion chamber is not fixed tight enough, possibly by vibration during driving. We solved it by tightening the two nuts fixing the shield.

Stove does not start

- Cause/remedy 1: diesel is of poor quality. The "flashpoint" (the lowest temperature at which there will be enough flammable vapor to ignite when an ignition source is applied) can vary between 52 and 96 degrees Celsius, depending on the type of diesel and the fuel can be contaminated. Dallas recommends to burn 10 liter of kerosene/paraffin after burning 250 liter of diesel. If you have a separate container for the stove fuel, it is best to use always kerosene, it has a lower flashpoint (between 37 and 65 degrees Celsius) and keeps the combustion chamber cleaner. A diesel heater can run on kerosene without problems as well;

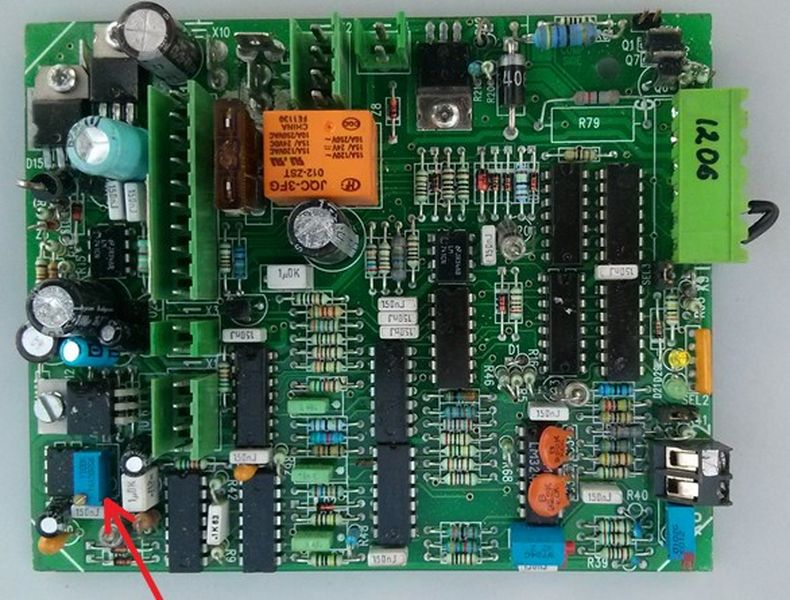

- Cause/remedy 2: glow plug contacts are poor. The voltage applied to the glow plug is less than 12 V. If this is caused by a poor connection between printed circuit board and glow plug (also the ground return line) you will not measure it by measuring the supply voltage to the stove. Clean the connections with a piece of sandpaper if needed;

- Cause/remedy 3: mat in combustion chamber is not clean. Inside the combustion chamber is a fiberglass mat that helps increasing the surface over which the fuel is spread out. The bigger the surface, the easier the ignition. Replace it, clean it very carefully or turn it such that the cleanest part is closest to the glow plug. See the service manual for dismounting/mounting instructions;

- Cause/remedy 4: battery voltage is too low: the 11 V as specified by Wallas is incorrect, you should target at 14 V This is the most important reason for failure. We tried to overcome this by switching off all other electricity consumers (lamps and fridge) and also by running the car engine while starting. We heard later from other Wallas users that they installed an additional device that keeps the glow voltage at 14 V independent of the battery voltage.